Leather labels are mainly sewn on the back waist of jeans, and of course, they are also widely used on bags, handbags, shoes, hats, and other products. There are various kinds of materials of leather labels, including genuine leather, imitation leather, microfiber leather, canvas, horsehair, PVC, TPU… and so on. It can be expressed by giving LOGO or company-designated patterns on different materials.

The make of leather labels

The make of leather labels is generally hot pressing (high temperature and timed ironing), hot pressing, voltage (high frequency), silkscreen, laser, sewing, embroidery, hardware… etc. It mainly depends on the designer’s design content, which is reflected according to the theme that the designer wants to express. Different themes and different materials naturally require different craftsmanship to reflect. So there is a lot of attention to it.

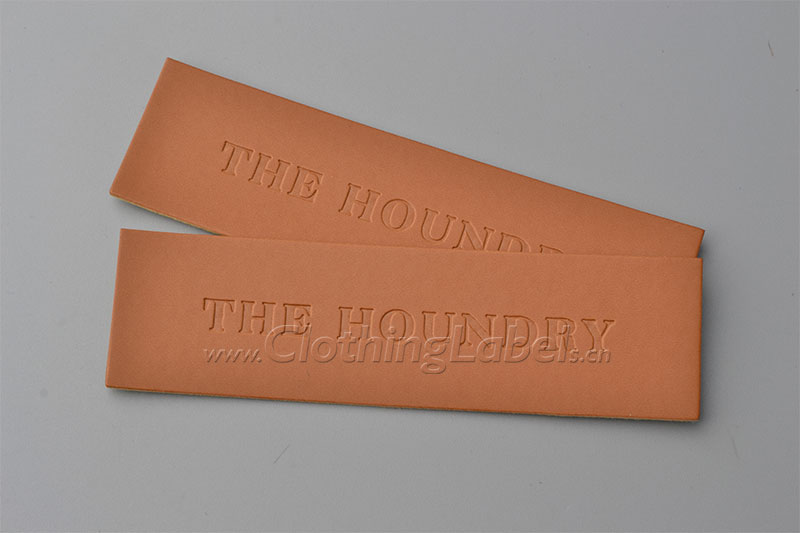

Image of leather labels

Designs of leather labels that seem to be simple are sometimes not that simple to make. And there is a lot of exquisiteness inside. It must be rich actual production experience to reflect subtle differences and ideal results. The same material with different masters will get different results. The production process cannot be defined simply and easily.

Different industries have different exquisites. No product in any industry can be underestimated. Each product has its unique charm. Thus, leather labels are no exception. Each design and manufacturing process is unique and irreplaceable.